PE Floats PU Foam Filled for Pipeline Laying

PE polyethylene floats made of plastic polyethylene shell with inner core polyurethane foam filled. Used as floating buoyancy material for sludge discharge pipelines in dredging industry. Polyethylene floats are replacing steel buoys due lighter weight and higher buoyancy. PE polyethylene floats are widely used for laying of pipelines for ocean, sea, salt lake, fishery, underwater oil and dredgings.

PE floats are made of reinforced materials of anti-corrosion, anti-freezing, anti-oxidation and anti-purification lines, not easily eroded by seawater, chemicals, oil stains and aquatic organisms. They produced in rotomolding process, no welding seams. PE polyethylene floats are classified into sands pumping pipe floats, pipline laying floats for dredging boats, fishery breeding pipeline floats, underwater pipelines laying floats, subsea pipline floater and dredging pipelines floats.

PE floats Features:

– Good toughness and impact resistance. especially suitable for offshore and constructions on the sea.

– Good toughness and impact resistance. especially suitable for offshore and constructions on the sea.

– Lighter weight with higher buoyancy. easily to be installed and handled, much lower transportant cost.

– Corrosion resistance. usage time up to 8 years.

– Lower cost than steel buoy or pontoon

– Temperature range -60~80 degrees

– Low water absorption rate

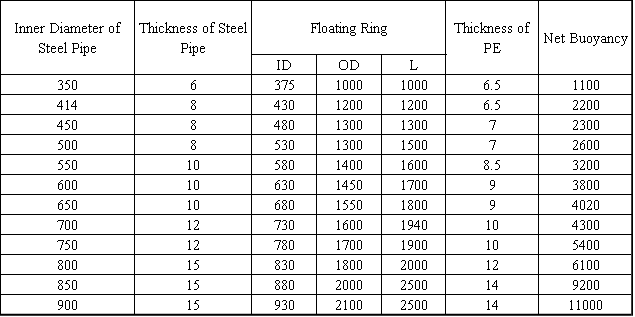

Specification of PE floats