We design marine foam fenders in shipboard type, this small standard duty SSD portable foam filled marine fender are installed sometime s together with bigger floating foam filled fenders. Marine foam filled fenders have limited storage space but providing tough heavy-duty marine fendering systemms for boat, Navy warship, and ship-to-ship applications.

Construction of shipboard foam fender

A. 100% closed cell and resilient foam core that is energy absorbing and cannot be ruptured are used to enhance the performance. This resilient foam-filled construction provides an unsinkable foam marine fender body that permits high energy absorption with a relatively low reaction force comparing with most other marine fendering systems.

B. Skin of our shipboard marine foam filled fenders is constructed of tough and thick nylon filament reinforced polyurethane skin. The skin also has a nylon tire cord applied in a helix pattern during the coating that embeds the filament into the skin. This advanced process makes small shipboard marine foam filled fenders skin extremely durable to all weather, forces and marine conditions.

C. Many optional fittings and design types are available as per clients’ requirement. All the material is hot dipped galvanzied steel.

- Small shipboard marine foam fenders ( with pad eye end fitings )

Small shipboard marine foam filled fenders ( with hawse pipe )

Small shipboard marine foam filled fenders ( with hawse pipe )- Portable floating marine foam filled fenders

Features & application of shipboard foam fender

- Lightweight and closed cell resilient foam core

- Tough, nylon filament reinforced polyurethane skin

- Various Optional Fittings and Designed Models

- Lightweight, and Easy Installation

- Ship-to-ship transfers, Ship-to-pontoon operation

- Small Boats, Yachts, Navy warships / Commercial Vessels

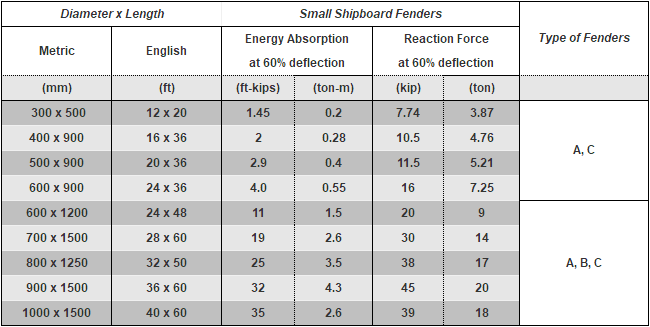

Performance of standard capacity:

Note:

- Actual values may vary 15% due to variation in materials, temperature, tolerances, and speed of compession.

- Type of marine foam filled fenders:

A – Small shipboard marine foam fenders ( with pad eye and fittings )

B – Small shipboard marine foam filled fenders ( with hawse pipe )

C – Portable marine fenders foam filled

D – Other sizes and designed models are available up to customers’ requirements

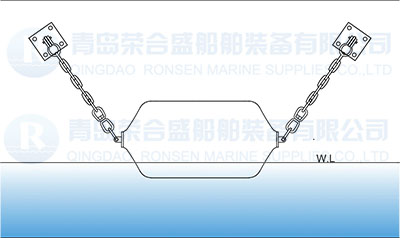

Installation of foam fenders

Floating foam filled marine fenders are easy be installed due its buoyant structure allows floating installation work. the unique craftship of end fittings and heavy duty internal chains also are ideal options for hanging installation. Whichever installation, it include a 2 points and 4 points mounting arrangement. The typical mounting hardwares include: dock plate padeyes, botls shackles, swivels and stud link chain. Please refer above photo.