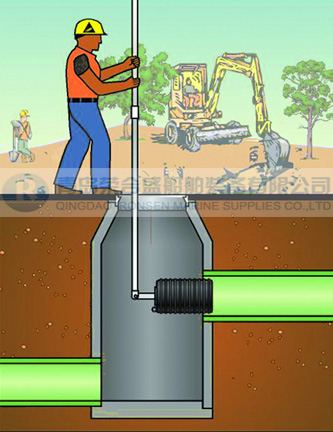

Rubber sealing airbag is one inflatable airbag embedded into underground to plug pipelines, closed and shut off water. Rubber plugging airbag is made of super heavy duty rubber layers to adapt to different water pressures, thus, there will be several types. The work principle of inflatable rubber sealing airbags is to provide friction when contacting the inner wall of pipelines and fully filled, this friction can block water shortly. Sealing rubber airbags we manufactured are high voltage resistant, good airtightness and anti-aging. They can work 1,000 hours continuously.

Rubber sealing airbag is one inflatable airbag embedded into underground to plug pipelines, closed and shut off water. Rubber plugging airbag is made of super heavy duty rubber layers to adapt to different water pressures, thus, there will be several types. The work principle of inflatable rubber sealing airbags is to provide friction when contacting the inner wall of pipelines and fully filled, this friction can block water shortly. Sealing rubber airbags we manufactured are high voltage resistant, good airtightness and anti-aging. They can work 1,000 hours continuously.

Application of rubber sealing airbag

Rubber airbag is a most common blocking tool for underwater pipelines, petroleum piplines, municipal construction and sewer pipelines engineerings. They are widely applied for pipelines sealing, repair and maintenance, leaking inspections etc. both suitable for sealing round pipelines and square pipelines.

Construction of rubber sealing airbags

Rubber sealing airbags are made of heavy duty rubber layers and multi-synthetic tire cords rubber dipped layers. Pressure can up to 1.0 Mpa, working time around 1,000 hours. Rubber sealing airbags can be used repeatedly without no leakage. The sealing plugging airbags is designed with cone heads with two arch ends.

Specification of sealing airbags

Common diameter, body length, working pressure of rubber sealing airbag are:

Diameter: 0.3m, 0.5m, 0.6m, 0.8m, 1.0m, 1.2m, 1.5m, 2.0m

Body length: 1.0 m to 5.0m

Working pressure: 0.2Mpa to 1.0Mpa

Our company produce customized sizes according to different working pressure, operating time, pipeline diameter as well engineering requirements.

Feature of sealing airbags

- Multi-size application

Plugs can be used in pipelines diameter than deflated diameter. Some seepage in smaller size pipelines will require a specific size vapor sleeve especially when pressure testing.

- Custom configuration

Custom flexible and rigid plugs can be manufactured for any shapes, high temperature, and severe chemical applications.