We manufacture three types cylindrical buoys: cylindrical buoys (CB), chain through buoys(CTB), pick up buoys(PUB). Cylindrical buoys are generally used for docking of marines, ships in oil gas offshore filed. They are generally called chain support mooring buoys. Cylindrical foam buoys are manufactured as marine fenders and foam filled fenders, constructed with closed cell EVA/PE foam core, sprayed polyurethane elastomer outer skin.

Construction of cylindrical buoy

Closed-cell EVA/PE foam core

The core is manufactured by batching up resilient closed cell EVA/polyethylene closed cell foam and uniformly continuously thermolaminating each layer together. This method ensures a bond stronger than closed cell foam itself and eliminates use of adhesives which can break down under long use. Using a polyethylene foam core ensure the foam buoy not abosrb water even if foam skin is punctured, increasing lifespan of foam buoys and reducing maintenance costs. This resilient foam material makes the foam buoys self fendering with a high impact absorption capacity.

Outer polyurethane skin

The foam core is encapsulated with a skin of high performance polyurethane elastomer, spray applied. Polyurethane elastomer is selected for the skin due to its high resistance to abrasion, fatigue and ultra violet degradation and its significantly more durable than polyethylene materials used in construction of rotationally moulded buoys.

Steelwork and end assembly

Comprising through central tube with longtitudal gussets and external load distribution flanges at each end. A swivel assembly, certified 10 tonnes SWL, with bows at each end passes through central tube.

All the material of swivel assembly are hot dip galvanized. Steelwork to be coal tar epoxy painted.

Material: Swivel assembly: bows to BS970

Gusets, flanges carbon steel to BS EN 10025 Fe 430 A or B

Central tube to BS 6323 Pt 3 HFS 5

Finsh: Swivel assembly hot dip galvanized to BS 729 Zn2/Zn4 at 610 g/m2

Steelwork to be coal tar epoxy painted

Skin Color: Orange, Yellow and others

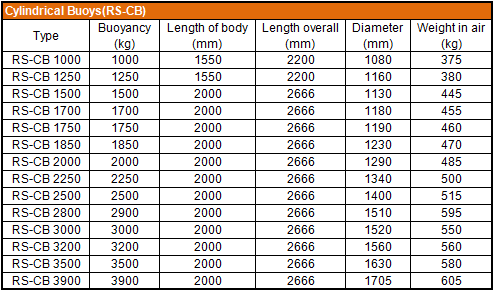

Cylindrical buoy (RS-CB)

- Designed central tension member to suit client’s requirement of safe working load

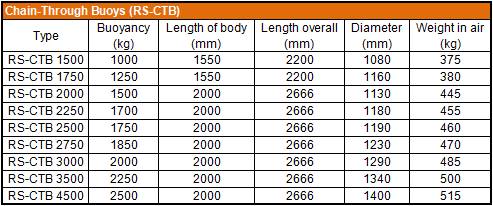

Chain through buoy (RS-CTB)

- Central tube for chain to pass through

- Securing the buoy to chain, chain locking device, on one and or both

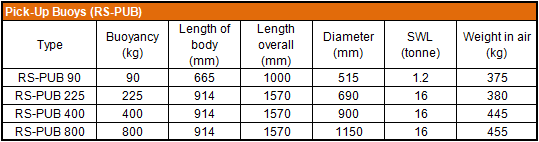

Pick up buoys (RS-PUB)

General purpose pick-up buoys are used for mooring, marker and pick-up duties.

General purpose pick-up buoys are used for mooring, marker and pick-up duties.